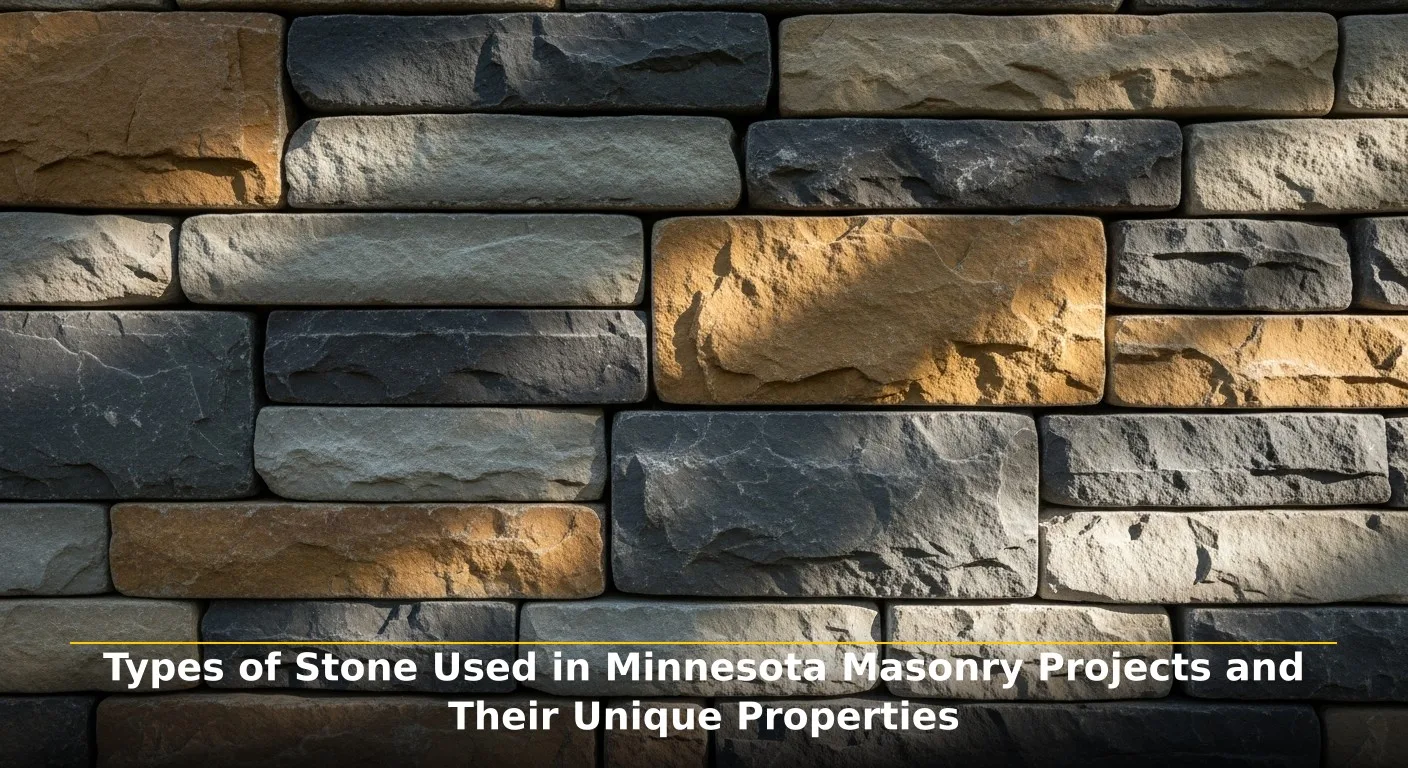

From the rugged North Shore to the rolling southern plains, Minnesota’s geology includes a rich palette of natural stone for masonry. Selecting the right stone is not an aesthetic decision; it’s a critical choice impacting a structure’s durability, maintenance, and performance against the state’s demanding climate.

This guide explores the most common types of natural stone used in Minnesotan masonry, detailing unique properties to help homeowners and builders make an informed decision for their next project.

1. The Bedrock of Minnesota Masonry: An Introduction to Local Stone

The four primary stones you will encounter are Granite, Limestone, Sandstone, and Fieldstone. Utilizing locally quarried stone is practical, as it is already acclimated to the environment, often providing inherent resilience to local weather patterns. Additionally, sourcing locally helps limit transportation costs and environmental impact, supporting regional economies.

2. Granite: The Unyielding Protector

Granite, an igneous rock cooled from molten magma, forms the very foundation of the Canadian Shield, which extends into Northeastern Minnesota. It’s one of the hardest stones on Earth.

A. Unique Properties

- Durability: Exceptionally high compressive strength and hardness. This is highly resistant to abrasion, impact, and weathering.

- Water Absorption: Extremely low (typically 0.5%), making it virtually impervious to freeze-thaw damage.

- Appearance: Granular texture with colors including speckled grays, pinks, blacks, and reds.

B. Local Highlight: Morton Gneiss

This rock, occasionally used as granite, is found in Renville County and is celebrated for its extreme durability and stunning visual appeal.

C. Applications

Granite is the champion of freeze-thaw resistance and ideal for structural and high-wear areas:

- Foundations & Retaining Walls.

- Patios & Walkways (perfect for high-traffic areas; resistant to de-icing salts).

- Commercial Facades for a permanent, low-maintenance exterior.

3. Limestone: The Refined Classic

Limestone is a sedimentary rock primarily formed from calcite. Minnesota limestone, including the famous Kasota Stone, is prized for its warm, consistent appearance and workability.

A. Unique Properties

- Durability: Commendable compressive strength but is softer than granite. It’s more susceptible to abrasion and acid erosion.

- Water Absorption: Moderate (typically 1%-5%). Performance varies by the specific layer and density of the stone.

- Appearance: Offers a uniform, smooth texture in a palette of warm buff, cream, gold, and light gray tones. It can be cut into precise ashlar patterns.

B. Local Highlight: Kasota Stone

This durable dolomitic limestone, quarried in southern Minnesota, is used in significant projects for consistent coloring and elegant look.

C. Applications

- Residential Facades & Veneer: Creates beautiful, refined exteriors.

- Commercial & Institutional Buildings.

- Patios & Garden Walls in less abrasive environments.

Maintenance Note: Its moderate porosity requires high-quality, vapor-permeable sealants to prevent spalling and deterioration from acidic rain and de-icing salts in harsh climates.

4. Sandstone: The Layered Storyteller

Sandstone is a sedimentary rock composed of sand-sized mineral particles cemented together. A defining characteristic is its visible layering and varied cementing agents.

A. Unique Properties

- Durability: Varies widely; silica-based sandstone is very durable, while calcite-based is softer.

- Water Absorption: Can range from moderate to high. Layered structures allow water to penetrate along bedding planes.

- Appearance: Distinctly layered look with a rich color palette, including browns, tans, reds, and grays. Features a rustic, textured feel.

B. Applications

- Garden & Landscape Walls.

- Veneer Accents on foundations or chimneys for rustic texture.

- Historic Restoration.

Disadvantage: Softer sandstones can be prone to delamination (splitting along layers) due to freeze-thaw cycles.

5. Fieldstone: The Authentic Native

Fieldstone is a classification for stones collected from the surface of fields or glacial deposits. In Minnesota, it’s primarily granite, basalt, or gneiss, shaped and smoothed by ancient glaciers.

A. Unique Properties

- Durability: Inherited from a parent rock (often durable granite), creating hard, weathered surfaces.

- Water Absorption: Generally low porosity, though it varies by stone type.

- Appearance: Characterized by their rounded, irregular shapes. It delivers a rustic, organic, and distinctly “Minnesota” look.

B. Applications

- Dry-Stack Retaining & Garden Walls: The quintessential use, creating permeable, natural-looking walls.

- Landscape Accents & Fire Pits.

- Chimney & Foundation Veneers.

Disadvantage: The irregular shapes make it time-consuming and challenging to lay in a mortared wall, increasing labor investment.

Comparative Guide: Minnesota Stone Properties at a Glance

Stone Type | Freeze-Thaw Resistance | Best Applications | Relative Investment Level | Key Maintenance Need |

Granite | Excellent | Foundations, Chimneys, Patios | Higher Investment | Minimal; occasional joint repointing |

Limestone | Good (with sealant) | Facades, Veneer, Formal Walls | Moderate to Higher Investment | Vapor-permeable sealing cycle |

Sandstone | Fair to Good (varies) | Garden Walls, Accents, Landscaping | Moderate Investment | Inspection for delamination |

Fieldstone | Good to Excellent | Dry-Stack Walls, Landscaping | Lower to Moderate Investment | Monitoring for settlement in walls |

6. The Professional’s Selection Guide: Full Stone vs. Veneer

Choosing the right material today often involves a crucial decision between Full-Bed Stone (traditional masonry) and Thin Stone Veneer (a modern, lighter approach).

A. Full-Bed Stone (Traditional)

- Thickness: Typically 3–5 inches deep.

- Weight: Significant.

- Structural Requirement: Requires a robust foundation or footing to bear its heavy weight.

- Durability: Necessary for structural walls, patios, and chimneys for maximum durability and traditional performance.

B. Thin Stone Veneer (Modern)

- Thickness: 1–1.5 inches deep.

- Weight: Significantly lighter than full-bed stone.

- Structural Requirement: Does not require a dedicated foundation.

- Cost-Effectiveness: An exceptional cost-effective and weight-saving alternative for facades and interior accents. It provides the same aesthetic with a simpler installation.

Key Consideration: The initial investment for thin veneer tends to be lower overall compared to full-bed stone due to reduced material weight and simpler installation.

Conclusion: Building a Legacy with Stone

The stone you choose becomes a permanent part of a property’s structure and story. From the unyielding strength of granite to the warm elegance of limestone, each option offers unique blends of beauty and resilience.

By understanding their physical properties and considering the budget and structural benefits of thin stone veneer versus full-bed stone, you can invest in a masonry feature that will withstand Minnesota’s demanding seasons for generations.

Frequently Asked Questions About Types of Stone Used in Minnesota Masonry Projects and Their Unique Properties

1. What Mortar Mix is Best for Natural Stone in Cold Climates?

A Type N mortar is generally recommended for non-structural veneers and walls, as it maintains a balance of strength and flexibility. Crucially, the mortar should be mixed with as little water as possible, and masonry should be protected from rapid freezing (by covering it) during the curing process to ensure maximum strength and prevent deterioration.

2. Can I use a pressure washer to clean my stone masonry?

It is not recommended to use high-pressure washing on stone masonry, especially on softer stones like some sandstones or limestones. Doing so can erode the mortar joints and damage the face of softer stone, increasing its porosity. A soft bristle brush and a mild, non-acidic masonry cleaner are the safest alternatives.

3. What is the difference between dry-stack and mortared walls?

A dry-stack wall uses no mortar; stones are fitted together so that gravity and friction hold them in place. These are great for garden walls and landscaping where flexibility is desired. A mortared wall uses mortar to bind the stones together, creating a more rigid, permanent, and often structural barrier, necessary for taller retaining walls or home facades.

4. How long does the mortar last compared to the stone itself?

The stone itself can last centuries, but mortar joints are the primary point of wear. Depending on the mix, exposure, and climate, mortar typically lasts between 25 to 75 years. When it begins to crumble or pull back from the stone, a process called repointing is necessary to rake out the old mortar and replace it with new, durable material.

5. Does the choice of stone affect property insurance premiums?

While many factors influence insurance costs, structures built with natural stone or brick masonry generally qualify for lower insurance premiums compared to wood or vinyl siding. This is because the stone’s inherent resistance to fire, wind, hail, and pests, making it a lower overall risk to the insurer.